NON-DESTRUCTIVE TESTING

The primary purpose of non-destructive testing is to obtain information about the physical condition, defects or properties of a product without changing its operational characteristics. It is a field that uses well-known physical laws and phenomena to evaluate the quality of the tested item without changing its characteristics and without compromising its serviceability.

Our engineers specialize primarily in the following non-destructive testing methods:

- visual,

- magnetic particle,

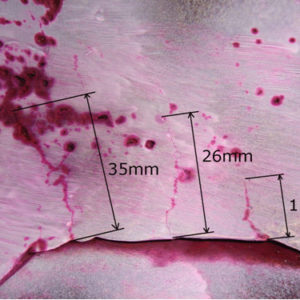

- penetrant,

- ultrasonic.

Our personnel are qualified and certified in accordance with PN-EN ISO 9712:2012 “Non-destructive testing. Qualification and certification of non-destructive testing personnel”. We perform all tests using supervised measuring equipment calibrated at authorized calibration laboratories:

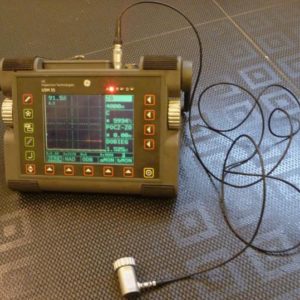

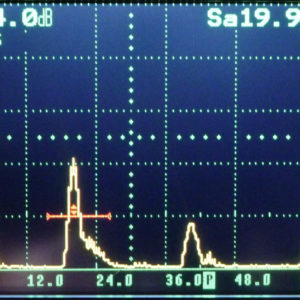

- ultrasonic testing – USM 35sx ultrasonic flaw detector,

- Magnetic particle testing – jaws flaw detector, fi350 coil, eddy current flaw detector with direct current flow in white light as well as ultraviolet light,

- Penetrant testing – in white light as well as ultraviolet light.

Upon your request, we are able to perform non-destructive testing for any type of material and equipment.

In particular, we perform non-destructive testing for the mining industry for the following. equipment and accessories:

Main shaft of the hoisting machine

Scope of research:

- Visual inspection of the main shaft.

- Ultrasonic inspection of the main shaft.

Load-bearing rope slings and equalizing rope slings for hoisting vessels

Scope of research:

- Visual inspection of load-bearing rope slings and equalizing rope slings for hoisting vessels.

- Ultrasonic inspection of load-bearing rope slings and equalizing rope slings for hoisting vessels.

- Magnetic particle testing of suspension of support ropes and suspension of alignment ropes of hoisting vessels.

Pressure equipment

Scope of research:

- Visual inspection of pressure equipment.

- Ultrasonic inspection of pressure equipment.

- Magnetic particle testing of pressure equipment (for ferritic steel).

- Penetrant testing of pressure equipment (for austenitic steel).

- Safety devices functionality check.

Rope sheaves

Scope of research:

- Visual inspection of the rope sheave.

- Magnetic particle testing of the rope sheave.

Rope sheave shafts

Scope of research:

- Visual inspection of the rope sheave shaft.

- Magnetic particle testing of the rope sheave shaft.

- Ultrasonic inspection of the rope sheave shaft.

Brake lever system components and components of the brake trigger of the hoisting machine

Scope of research:

- Visual inspection.

- Magnetic particle testing.

- Ultrasonic inspection.

Hoisting vessels

Scope of research:

- Visual inspection of the hoisting vessel.

- Magnetic particle testing of the hoisting vessel.

- Measurements of the thickness of the load-bearing elements of the hoisting vessel.

Regardless of what sector we operate in, mining, electrical energy, or any other, we conduct our non-destructive testing services while ensuring quality and process safety.

JANUSZ LEWANDOWSKI:

| CALL: | +48 508 120 232 |

| WRITE AT: | januszlewandowski@opa.pl |